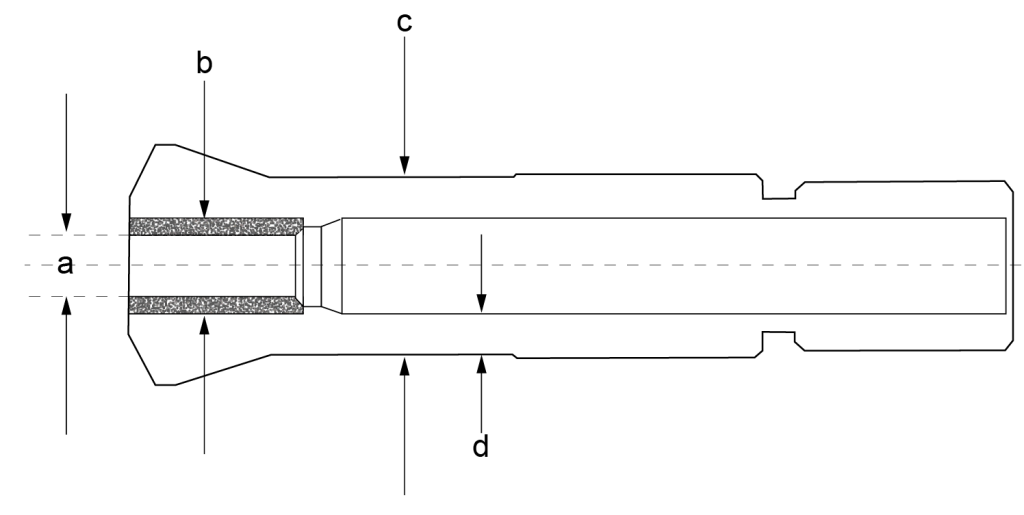

Introdution: When running swiss lathe, carbide guide bushing will be used to hold the small and longer bar to make high performance and stability,so that guide bushing can be done high precision machining job. Mostly guide bushing will be required making with carbide inside the clamping hole (see ‘b’ from image below) for wear-assistant reason.

However, sometimes we happened to one situation, when you give the bar dia. to collet manufacturer, they might said that the guide bushing can not go ahead with carbide technology.

And the mainly reason leads to:

(c-b)/2 =d value of guide bushing,we regarding it as Neck-Side value

Impact of Neck-Side:

Neck-Side plays a significant role in determining the stability of the guide bushing while clamping workpiece. Neck-Side value must be within reasonable range to make sure the guide bushing performance.

The clamping forth mainly occurs to the Bigger Outside Dia where hardness is about HRC50, and the b position hardness is about HRC40. Consequently, after a very few short time working,the connection between the Bigger Oudside Dia and b Position will easy to be break while Neck-Side value is too small.

Recommended Neck-Side value:

The recommended Neck-Side value depend on guide bushing type. For instance, the TD7 bushing suggests Neck-Side value≥1mm, while the TD32 & TD32S guide bushes recommend Neck-Side value≥2.5mm.

Practical Example:

Let’s consider the TD7 guide bushing with a large outer diameter of 14.5mm, where c = 10.5. Assuming a hole size of a = 7.0mm and the addition of tungsten carbide resulting in b = 9.0mm, the calculated Neck-Side value is 0.75mm. In this scenario, it is not advisable to make guide bushing with carbide inside the hole.

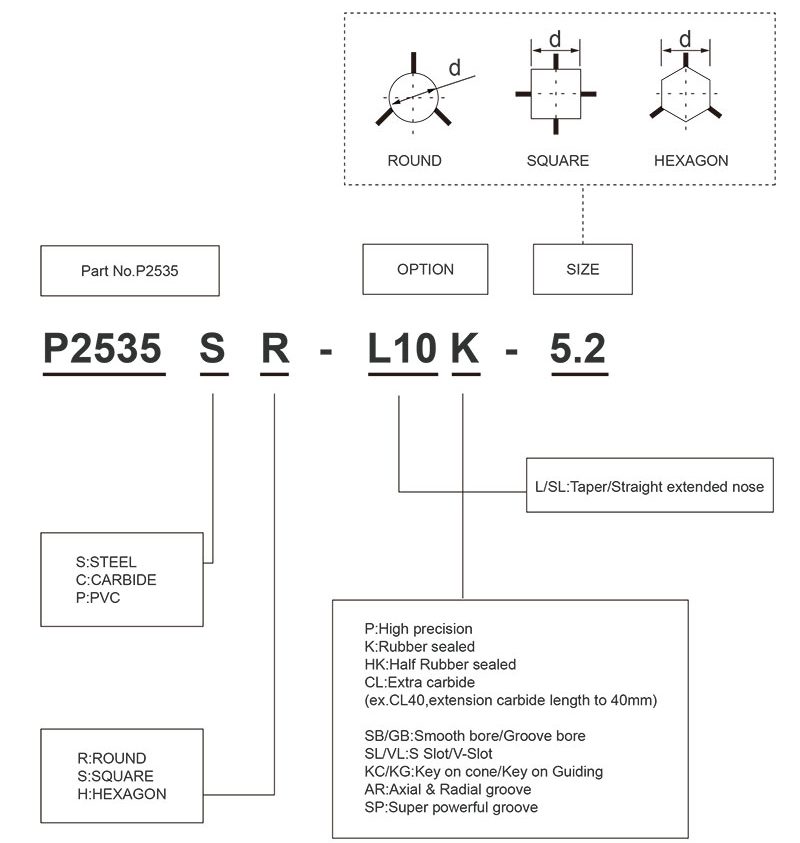

Pls check Part No written method as per...

This July, we will set to host a important visit from our Indian...

©2023 Shenzhen Zeling Precision Industry Co., Ltd. All rights reserved