1、Quick-Change Design: Compared to other types of boring tools, this design allows for rapid tool changes, significantly reducing downtime and enhancing productivity in your CNC machining processes.

2、Wear-Resistant Coating: Available in multiple coating options to suit different metal materials, providing enhanced durability and performance, and supporting the machining of materials up to HRC60° hardness.

3、80° Cutting Angle: ideal for micro boring tasks and detailed machining operations.

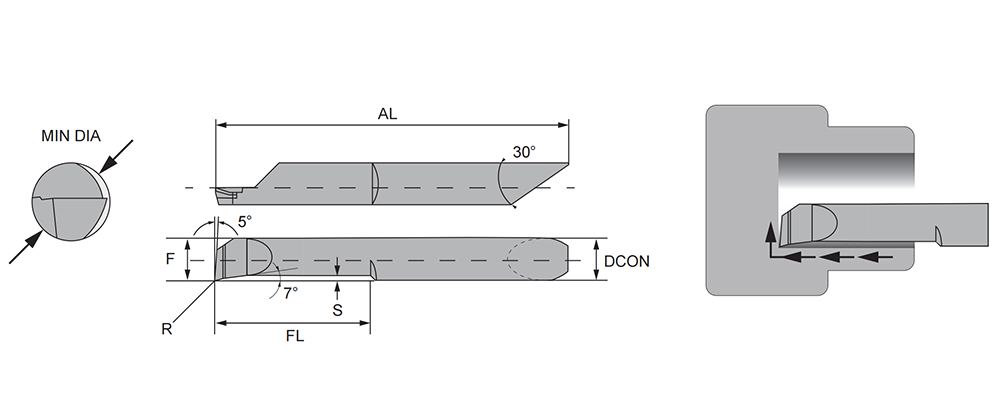

| PART NO | MIN DIA | DCON | R | AL | FL | F | S |

| PMS04T2106005R | 2.1 | 4 | 0.05 | 31 | 6 | 1.85 | 0.20 |

| PMS04T2106010R | 2.1 | 4 | 0.10 | 31 | 6 | 1.85 | 0.20 |

| PMS04T2110005R | 2.1 | 4 | 0.05 | 35 | 10 | 1.85 | 0.20 |

| PMS04T2110010R | 2.1 | 4 | 0.10 | 35 | 10 | 1.85 | 0.20 |

| PMS04T2608005R | 2.6 | 4 | 0.05 | 33 | 8 | 2.35 | 0.25 |

| PMS04T2608010R | 2.6 | 4 | 0.10 | 33 | 8 | 2.35 | 0.25 |

| PMS04T2608015R | 2.6 | 4 | 0.15 | 33 | 8 | 2.35 | 0.25 |

| PMS04T2612005R | 2.6 | 4 | 0.05 | 37 | 12 | 2.35 | 0.25 |

| PMS04T2612010R | 2.6 | 4 | 0.10 | 37 | 12 | 2.35 | 0.25 |

| PMS04T2612015R | 2.6 | 4 | 0.15 | 37 | 12 | 2.35 | 0.25 |

| PMS04T3110005R | 3.1 | 4 | 0.05 | 35 | 10 | 2.8 | 0.30 |

| PMS04T3110010R | 3.1 | 4 | 0.10 | 35 | 10 | 2.8 | 0.30 |

| PMS04T3110015R | 3.1 | 4 | 0.15 | 35 | 10 | 2.8 | 0.30 |

| PMS04T3115005R | 3.1 | 4 | 0.05 | 40 | 15 | 2.8 | 0.30 |

| PMS04T3115010R | 3.1 | 4 | 0.10 | 40 | 15 | 2.8 | 0.30 |

| PMS04T3115015R | 3.1 | 4 | 0.15 | 40 | 15 | 2.8 | 0.30 |

| PMS04T4112005R | 4.1 | 4 | 0.05 | 37 | 12 | 3.8 | 0.40 |

| PMS04T4112010R | 4.1 | 4 | 0.10 | 37 | 12 | 3.8 | 0.40 |

| PMS04T4112020R | 4.1 | 4 | 0.20 | 37 | 12 | 3.8 | 0.40 |

| PMS04T4116005R | 4.1 | 4 | 0.05 | 41 | 16 | 3.8 | 0.40 |

| PMS04T4116010R | 4.1 | 4 | 0.10 | 41 | 16 | 3.8 | 0.40 |

| PMS04T4116020R | 4.1 | 4 | 0.20 | 41 | 16 | 3.8 | 0.40 |

| PMS04T4120005R | 4.1 | 4 | 0.05 | 45 | 20 | 3.8 | 0.40 |

| PMS04T4120010R | 4.1 | 4 | 0.10 | 45 | 20 | 3.8 | 0.40 |

| PMS04T4120020R | 4.1 | 4 | 0.20 | 45 | 20 | 3.8 | 0.40 |

| PMS05T5115010R | 5.1 | 5 | 0.10 | 40 | 15 | 4.8 | 0.50 |

| PMS05T5115020R | 5.1 | 5 | 0.20 | 40 | 15 | 4.8 | 0.50 |

| PMS05T5120010R | 5.1 | 5 | 0.10 | 45 | 20 | 4.8 | 0.50 |

| PMS05T5120020R | 5.1 | 5 | 0.20 | 45 | 20 | 4.8 | 0.50 |

| PMS05T5125010R | 5.1 | 5 | 0.10 | 50 | 25 | 4.8 | 0.50 |

| PMS05T5125020R | 5.1 | 5 | 0.20 | 50 | 25 | 4.8 | 0.50 |

| PMS06T6115010R | 6.1 | 6 | 0.10 | 40 | 15 | 5.8 | 0.60 |

| PMS06T6115020R | 6.1 | 6 | 0.20 | 40 | 15 | 5.8 | 0.60 |

| PMS06T6120010R | 6.1 | 6 | 0.10 | 45 | 20 | 5.8 | 0.60 |

| PMS06T6120020R | 6.1 | 6 | 0.20 | 45 | 20 | 5.8 | 0.60 |

| PMS06T6125010R | 6.1 | 6 | 0.10 | 50 | 25 | 5.8 | 0.60 |

| PMS06T6125020R | 6.1 | 6 | 0.20 | 50 | 25 | 5.8 | 0.60 |

| PMS06T6130010R | 6.1 | 6 | 0.10 | 55 | 30 | 5.8 | 0.60 |

| PMS06T6130020R | 6.1 | 6 | 0.20 | 55 | 30 | 5.8 | 0.60 |

| PMS07T7125010R | 7.1 | 7 | 0.10 | 54 | 25 | 6.8 | 0.70 |

| PMS07T7125020R | 7.1 | 7 | 0.20 | 54 | 25 | 6.8 | 0.70 |

| PMS07T7135010R | 7.1 | 7 | 0.10 | 64 | 35 | 6.8 | 0.70 |

| PMS07T7135020R | 7.1 | 7 | 0.20 | 64 | 35 | 6.8 | 0.70 |

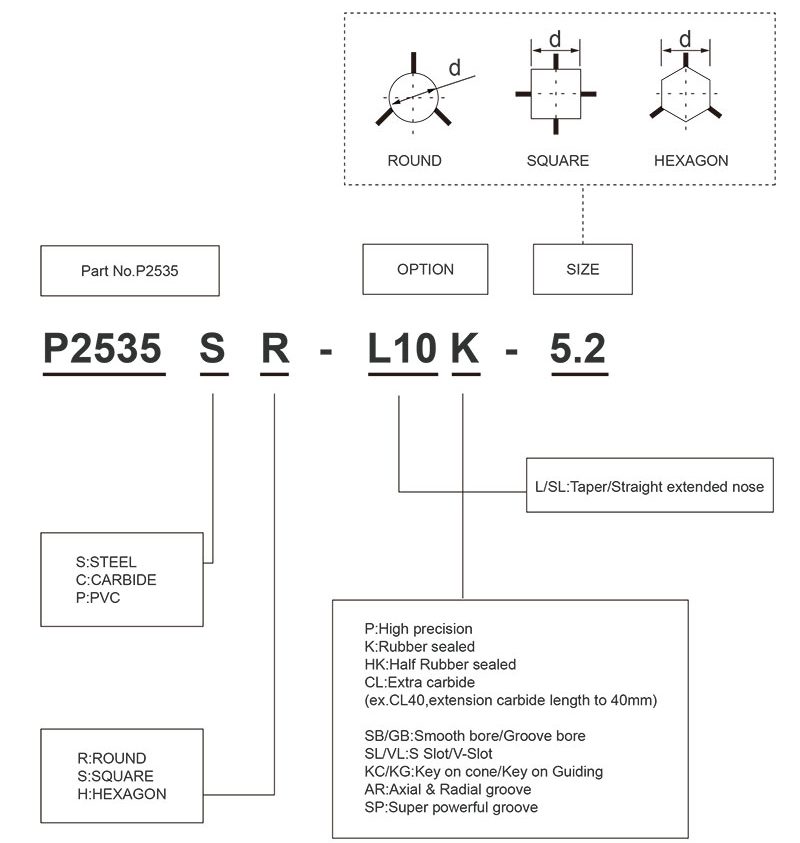

Pls check Part No written method as per...

This July, we will set to host a important visit from our Indian...

©2023 Shenzhen Zeling Precision Industry Co., Ltd. All rights reserved